Precise Flow

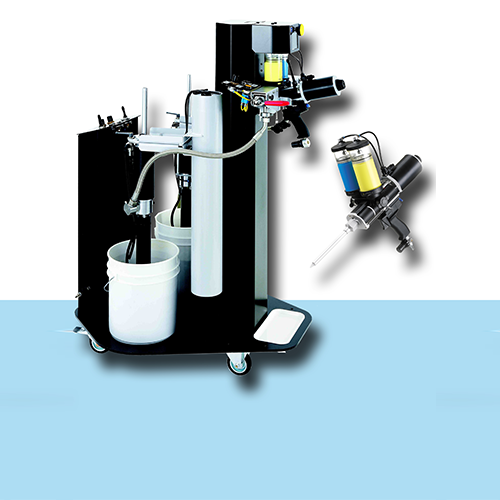

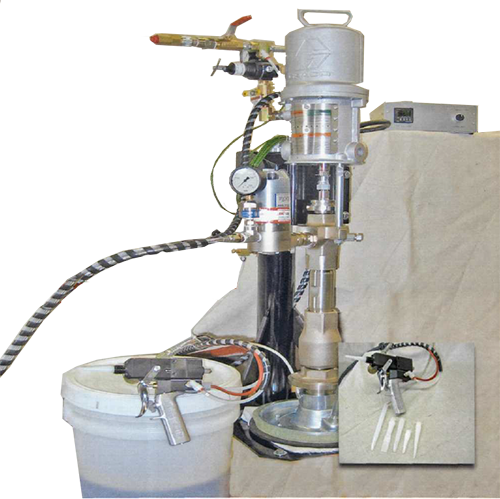

For applying beads with high viscosity materials the Ashby Cross Bead Dispenser pumps directly from the manufacturers 5-gallon or 55-gallon containers directly to the precision gear meter. The gear meter provides precise flow control which yields excellent bead geometry and repeatability.

Features include a flow balanced, pneumatically driven, 5-gallon or 55-gallon ram inducted feed pump and precision gear meter with variable flow capability which may be controlled manually or by PLC. A wide range of industrial dispense valves and nozzles may be mounted to achieve the desired bead geometry.

The unit is available as a stand-alone system, mounted on a portable cart, or bench-top mounted.

Used in bead laying applications that require exact adhesive geometry and repeatability in continuous or intermittent operation.

Brochure

Manually Operated

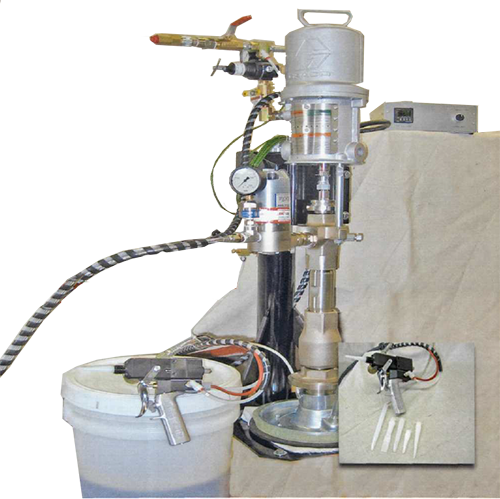

The Five Gallon Ram Inducted Pump System is similar to the Precision Flow Bead Dispenser. However the manual system relies on the flow balanced feed pump to control the amount dispensed.

Features include a flow balanced, pneumatically driven, 5-gallon or 55-gallon ram inducted feed pump and manual or robotic mounted industrial dispense valve. A wide range of valves and nozzles may be mounted to achieve the desired bead geometry.

The unit may be configured in a variety of ways including mounting on a portable cart.

Used in bead laying applications either continuous or intermittent that do not require precise geometry.

Contact us for selection assistance.

Brochure

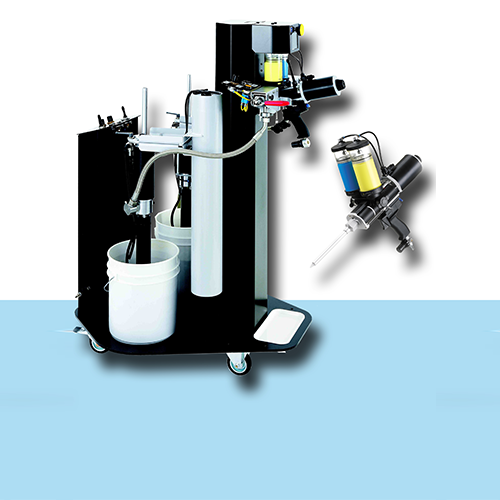

DXBG

Ideal for use with epoxy, silicone, urethane and acrylic, this machine features easy-to-fill 2-gallon reservoirs.

Read more

DXR Refill Station

The DXR Refill Station and DXH Dispenser are ideal tools for bonding applications needing mobility and multiple operators.

Read more

One Part Dispensing

From applications that require small, precision dispensing to ones that need large quantities of single component epoxies and adhesives, Ashby Cross has the right equipment for you.

Read more